- Home

- About us

- Products

- Stadium Athletics Track

- Artificial Grass

- College | University | School Rubber Running Track

- Pickleball Court Flooring

- Kindergarten Synthetic Playing Surfaces

- Sport Court Surface

- Basketball Court Flooring

- Tennis Court Flooring

- Rubber Gym Flooring

- Park Jogging Track Rubber Flooring

- Massage Mat

- Construction Tools

- Faqs

- News

- Certificate

- Contact us

Laying the Prefabricated Rubber Track Sheets: A Step-by-Step Guide

publisherDonna

time2025/01/02

- The process of laying prefabricated rubber track sheets is a crucial step in building high-performance running track surfaces. Proper installation ensures the track's durability, functionality, and compliance with international standards. This guide outlines the precise steps and considerations involved in laying synthetic athletic track sheets, emphasizing quality, efficiency, and safety.

The process of laying prefabricated rubber track sheets is a crucial step in building high-performance running track surfaces. Proper installation ensures the track's durability, functionality, and compliance with international standards. This guide outlines the precise steps and considerations involved in laying synthetic athletic track sheets, emphasizing quality, efficiency, and safety.

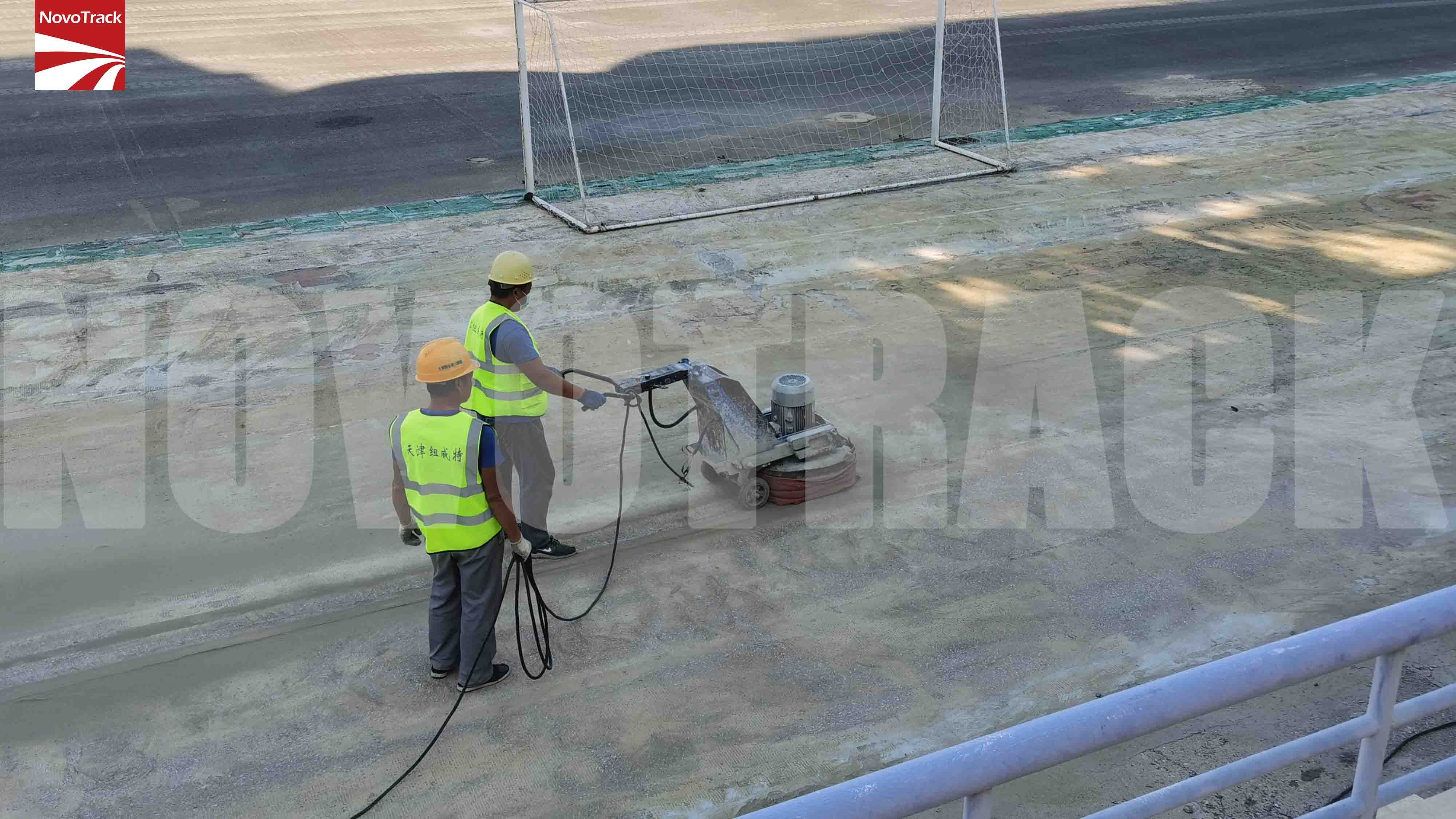

1. Preparation Before Laying the Track Sheets

(1) Site Inspection and Measurement

· Conduct a detailed inspection of the prepared base layer (typically asphalt or concrete) to ensure it is clean, level, and free of debris.

· Verify that the surface meets specifications, including flatness and slope requirements.

· Reconfirm dimensions and layout based on the 400m athletics track design.

(2) Adhesive Application

· A specialized adhesive is evenly applied to the base layer to bond the prefabricated rubber sheets securely.

· The adhesive must be spread uniformly to prevent air pockets, which can compromise the track's durability and performance.

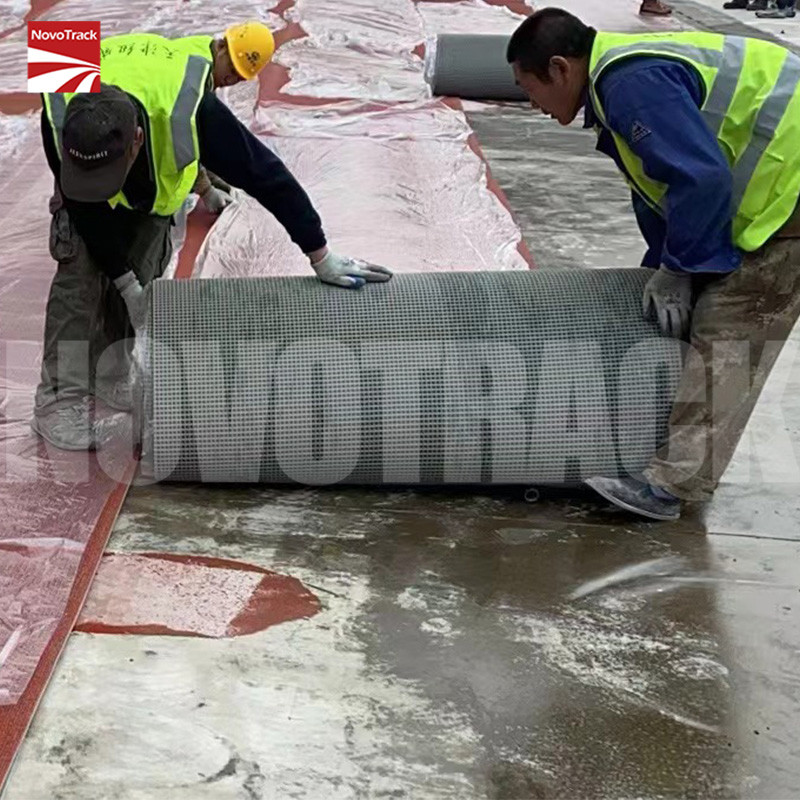

2. Positioning the Prefabricated Rubber Sheets

(1) Aligning the Sheets

· Precise alignment is critical to ensure that the track lanes are seamless and straight.

· Starting with the innermost lane, lay the sheets edge-to-edge, ensuring no gaps between sections.

(2) Adjusting for Curves

· On curved sections of the track, carefully trim and position the sheets to match the curve's radius.

· Use specialized cutting tools to achieve clean edges and precise fitting.

3. Securing and Bonding the Track Sheets

(1) Rolling for Adhesion

· After positioning, use heavy rollers to press the sheets firmly against the adhesive base.

· Rolling ensures proper bonding and eliminates air bubbles for a smooth surface.

(2) Seaming and Joining

· Seamless joints are critical for track performance and safety.

· Specialized sealants or hot welding techniques are used to join adjacent sheets, creating a uniform surface that withstands stress and weather.

4. Quality Checks During and After Installation

(1) Surface Uniformity

· Inspect the track for any irregularities, such as wrinkles, gaps, or uneven sections.

· Make immediate adjustments to maintain a flat and consistent surface.

(2) Adhesion Testing

· Conduct adhesion tests to ensure the prefabricated sheets are securely bonded to the base layer.

· Weak spots are repaired immediately to prevent future issues.

(3) Environmental Conditions

· Installation should occur in controlled weather conditions, avoiding extreme temperatures or moisture that can affect adhesive curing.

5. Final Surface Treatment

(1) Anti-Slip Coating

· Depending on the project requirements, an anti-slip coating may be applied to enhance grip and safety.

· This layer also adds durability and resistance to wear.

(2) Line Marking

· Once the track sheets are installed, precise line marking is applied to define lanes and event areas.

6. Challenges in Laying Prefabricated Rubber Track Sheets

(1) Ensuring Precision

· Aligning sheets perfectly, especially on curved sections, requires skilled labor and high-precision tools.

· Solution: Use experienced installation teams and advanced equipment for accuracy.

(2) Weather Dependency

· Installation must be planned around suitable weather conditions to ensure proper adhesive curing and sheet bonding.

· Solution: Monitor forecasts and prepare for contingencies during the installation phase.

(3) Seam Durability

· Poorly joined seams can lead to surface issues and reduce track longevity.

· Solution: Employ high-quality sealants and thorough rolling techniques to create seamless connections.

7. Benefits of Prefabricated Rubber Track Sheets

(1) Efficiency in Installation

· Prefabricated sheets reduce construction time compared to traditional poured-in-place methods.

· The streamlined process minimizes disruptions and project delays.

(2) Superior Surface Quality

· Prefabricated sheets ensure uniform thickness and consistent performance across the track.

· This guarantees optimal shock absorption, energy return, and durability.

(3) Cost-Effective Maintenance

· With fewer joints and a durable design, prefabricated tracks require minimal maintenance, reducing long-term costs.

Conclusion

Laying prefabricated rubber track sheets is a meticulous yet efficient process that forms the foundation of a high-performance synthetic athletic track. By adhering to best practices in preparation, alignment, bonding, and quality control, facilities can ensure a durable, safe, and visually appealing 400m athletics track.

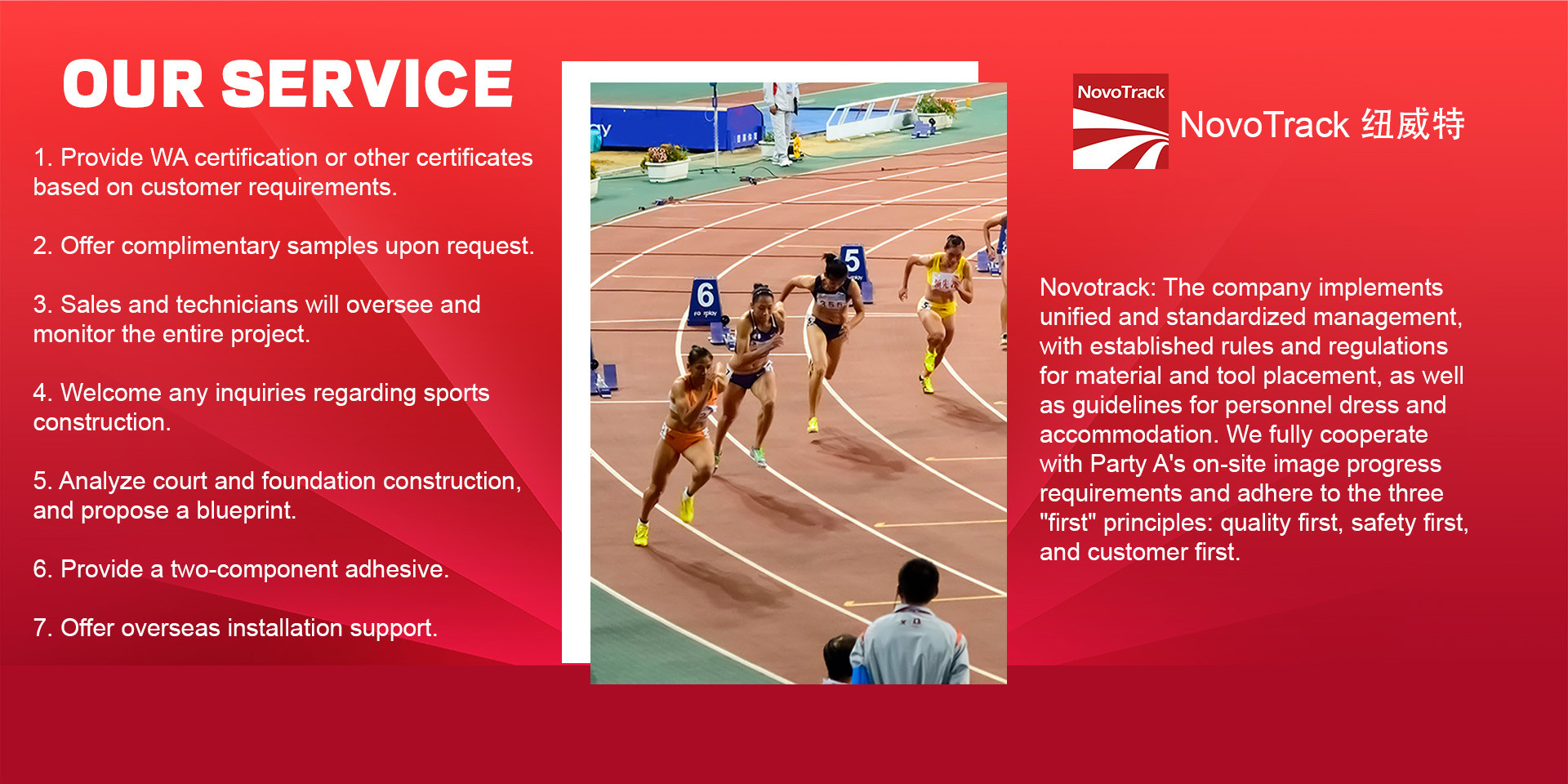

NovoTrack specializes in delivering expertly installed running track surfaces, combining precision craftsmanship with top-tier materials. Trust us to bring your vision of a world-class athletic facility to life.

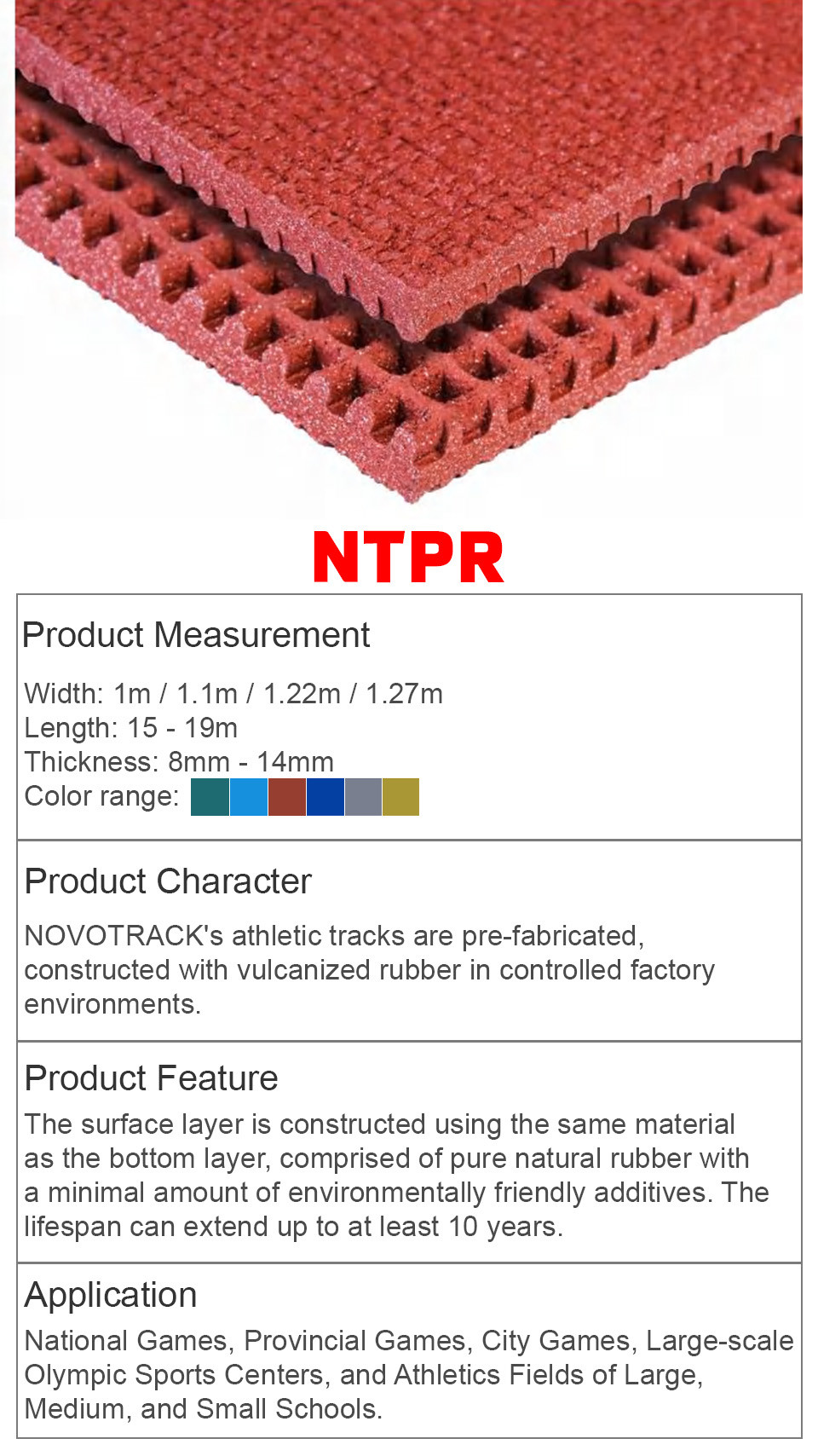

Related Products

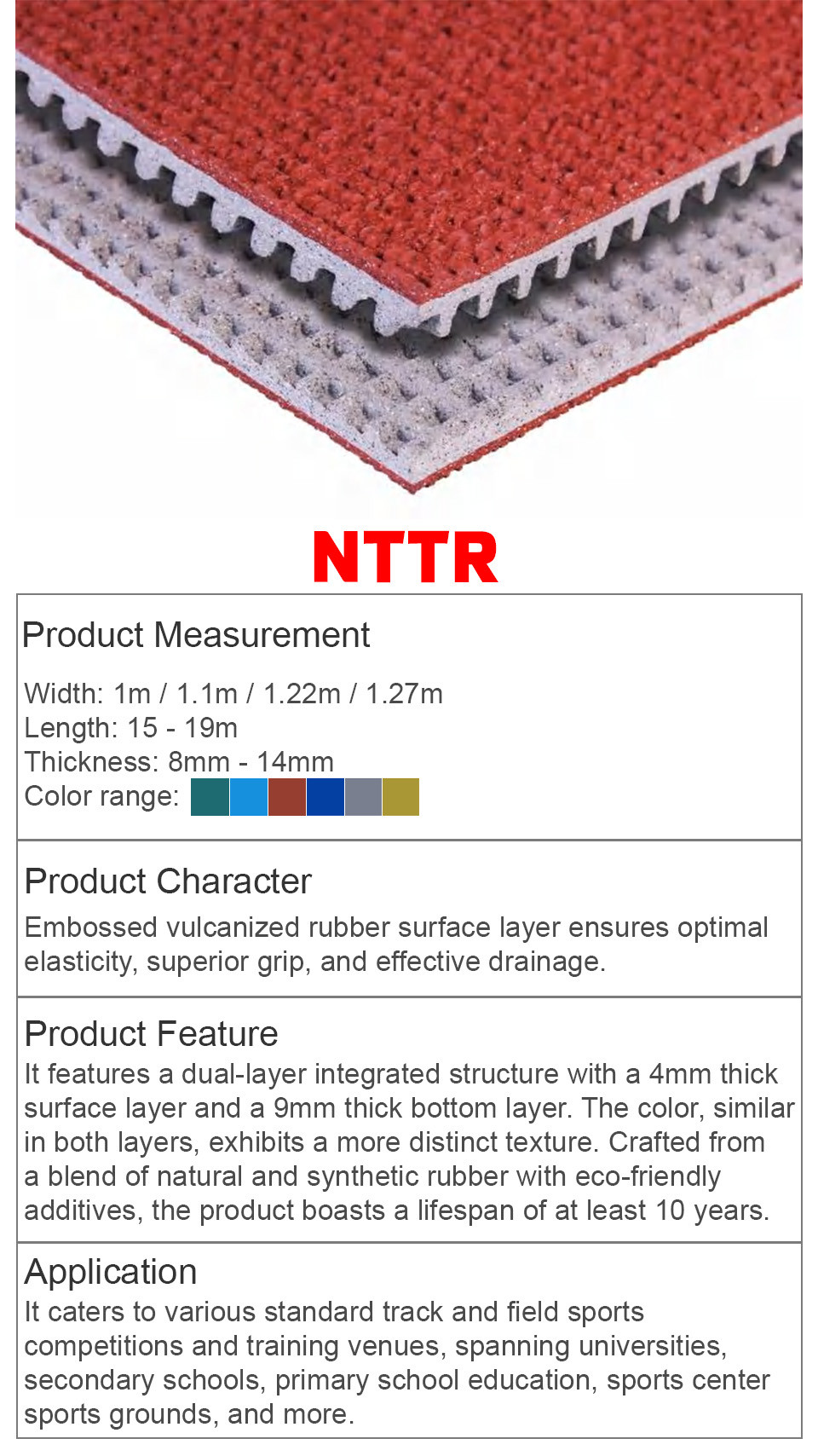

NovoTrack's prefabricated rubber running track strictly follows the standards of the World Athletics.

Prefabricated rubber running track flooring is a sports surface paving material specially designed for track and field sports. It's made of natural rubber and synthetic rubber.

WA rubber running track and field surface, tartan athletics track for stadium,Prefabricated Rubber Running Track.